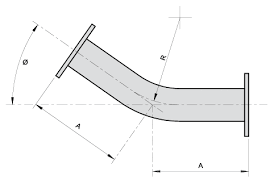

Pulled Bend

Pulled Bend

Mesta Inc stands as a premier manufacturer and exporter of high-quality pulled bend fittings, delivering excellence to clients across Kazakhstan, India, UAE, Saudi Arabia, and Uzbekistan. Known for our reliability and precision, we serve industries where quality and durability are non-negotiable.

A pulled bend is a seamless pipe bend created through cold-drawing techniques, ensuring consistent flow and strength. Compared to welded or elbow bends, pulled bends offer better internal smoothness, reduced turbulence, and a more uniform shape, making them ideal for high-performance piping systems.

Thanks to our advanced facilities and expert engineering team, Mesta Inc continues to lead in producing bends that exceed global standards.

High-Quality Pulled Bend Supplier in Saudi Arabia and India

As a trusted pulled bend supplier in Saudi Arabia and India, Mesta Inc offers both standard and custom-size fittings to meet the diverse demands of various industries. Our production process involves cold-pulling seamless pipes over a die, which ensures excellent dimensional accuracy and a flawless interior surface.

This method not only eliminates welding seams but also significantly improves pressure-handling capacity. Moreover, our bends are available in a range of radii, wall thicknesses, and diameters, enabling flexible usage in both compact and large-scale systems.

Because safety and quality are always our priority, each pulled bend undergoes strict non-destructive testing, surface treatment, and dimensional inspection before shipment.

Our engineers provide end-to-end support—from selecting the right material grade to ensuring timely delivery—making us a reliable partner in pipeline construction projects.

Applications and Advantages of Pulled Bends

Pulled bends play a critical role in systems that demand seamless flow and minimal pressure loss. Industries across Kazakhstan, Uzbekistan, and the UAE use them in applications such as:

Oil and gas transmission

Petrochemical processing

Power generation

Water treatment facilities

Structural and mechanical pipelines

One of the most notable advantages of using pulled bends is their ability to reduce welding points in a pipeline. Fewer joints mean lower chances of leaks, which translates to enhanced safety and lower maintenance costs.

Furthermore, their smooth internal surface ensures unrestricted flow of fluids, reducing wear and tear caused by turbulence. This contributes to higher energy efficiency and longer equipment life.

From tight-space industrial plants in India to large-scale desert pipelines in Saudi Arabia, our pulled bends offer unmatched performance across diverse environments.

Material Grades, Sizing, and Coating Options

Mesta Inc manufactures pulled bends in various carbon steel, alloy steel, and stainless steel grades, depending on the client’s operating temperature, pressure, and corrosion resistance needs. Our commonly used standards include:

ASTM A234 WPB

ASME B16.9

EN 10253-2

DIN 2605

Whether the client requires long-radius bends for smoother transitions or short-radius bends for compact systems, our manufacturing capabilities are flexible enough to deliver both small and bulk quantities with precision.

To enhance durability, we also offer several surface treatments such as:

Black painting

Galvanization

Anti-corrosion epoxy coating

Sandblasting and pickling

These treatments help the pulled bends withstand aggressive environments—whether it’s salt-laden air in UAE or freezing winters in Uzbekistan.

Why Choose Mesta Inc for Pulled Bend Manufacturing

Mesta Inc’s success is built on three pillars: quality, customization, and customer satisfaction. Our pulled bends are manufactured in state-of-the-art facilities that operate under strict ISO-certified processes.

Here’s why leading companies across India, Kazakhstan, and the UAE trust us:

Modern machinery and skilled workforce

Short lead times and on-time delivery

Global supply chain and export expertise

Full compliance with international codes

100% traceability and documentation

Additionally, we provide tailored solutions for EPC contractors, oil field developers, and infrastructure firms. Even when project requirements are complex, our design engineers and project managers work closely with clients to deliver accurate, project-ready products.

We don’t just sell components—we help optimize systems. And because time is critical in industrial projects, we also offer expedited delivery services and regional warehousing in Saudi Arabia and India.

Logistics and Regional Support Across Central Asia and the Middle East

Understanding local needs is key to successful supply. Mesta Inc has built a strong distribution network across Kazakhstan, Uzbekistan, and the Middle East, enabling us to offer faster delivery and better technical assistance.

Our regional presence allows us to maintain buffer stocks and respond swiftly to urgent requirements. We also manage international shipping, documentation, customs clearance, and packaging—so that our clients can focus on operations instead of logistics.

In markets like Uzbekistan, our pulled bends are widely used in government-led infrastructure projects and private sector developments. In Kazakhstan, our seamless cold-drawn bends are valued for pipeline reliability under high pressure and extreme weather conditions.

Because of this regional strength and responsiveness, Mesta Inc is considered a go-to supplier in both standard and custom bend requirements.

With every pulled bend we produce, our mission is clear: deliver strength, efficiency, and long-term reliability in every project.

By choosing Mesta Inc, industries gain more than just a fitting—they gain an assurance of performance, safety, and success. As the world advances and industrial challenges evolve, we remain ready with solutions that meet the highest expectations.